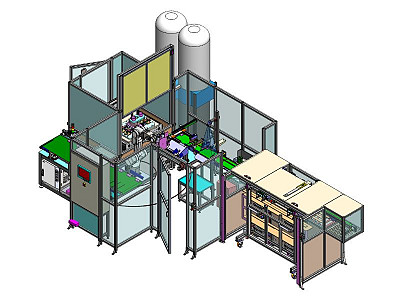

Automated Kerrock sample production line

For the client, we developed and built a fully automated line for producing samples from the composite material Kerrock, used in architecture and industry. The project aimed to increase productivity, reduce costs, ensure consistent quality, and reduce reliance on manual labor. The key innovation is a special cutting tool that shapes the samples and delivers a polished surface in a single step, eliminating the need for a multi-stage grinding process.

Initial challenge – Before automation, the existing processes required six operators working two shifts, with grinding being multi-stage and time-consuming. The client sought a solution that would enable full process automation, increase capacity, ensure consistent surface quality, and reduce manual labor and unnecessary handling.

Result – A fully automated line was implemented, integrating a servo-controlled saw, an optical measuring system, a 6-axis robot, a CNC milling machine, and an automatic raw material feeder. The number of operators was reduced from six to one, and annual capacity increased from 300,000 to 500,000 pieces. The process became repeatable, reliable, and adaptable to various sample sizes.

Key technological features of the line

The production line uses a specially designed cutting tool with a geometry that enables simultaneous side milling and edge chamfering in a single step, achieving the highest possible surface quality within the available cycle times. This design reduces the need for multi-stage grinding, speeds up the process, and ensures a uniform, “polished” edge surface. The tool is optimized for minimal dust formation and long service life, allowing precise machining of various sample dimensions.

The clamping of raw pieces is ensured by a combination of vacuum and mechanical force for smaller workpieces.

Vacuum clamping table in a CNC milling machine

The optical measuring system measures the thickness of each piece, which can vary by up to ±0.3 mm, and sends the data to the CNC milling machine. The machine then automatically adjusts the Z-axis height and processing parameters, ensuring high repeatability and flawless results regardless of variations in the raw material.

Alignment table for cut pieces with integrated optical thickness measurement

The robotic handling system features a specially designed multi-stage vacuum gripper, developed to protect the delicate surfaces of the pieces (already polished to a high gloss), accommodate varying dimensions, and support high-speed manipulation. This design ensures secure gripping without surface damage and adapts to a wide range of sample sizes. The robot provides fast, precise, and safe transport of raw and processed pieces between all modules of the line.

ABB IRB robot with vacuum gripper

The line includes

- Input raw material storage with trolleys and size separator,

- servo-controlled saw with automatic pusher,

- in-line vision system for sample recognition and measurement before machining,

- optical measuring system with dynamic software solution that adjusts the CNC machine to the height of the raw material,

- 6-axis ABB robot with vacuum grippers for handling raw and finished pieces,

- 3-axis CNC milling machine with specialized cutting tool,

- output conveyor for finished pieces,

- dust extraction system,

- Siemens S7 central control with operator interface.

From concept to execution – together with you

We don’t just deliver machines – we provide complete solutions, developed in close collaboration with our clients. Each project is designed with efficiency, reliability, and your long-term goals in mind.

Step-by-step operation of the automated line

1. Loading raw materials – Raw materials are placed in a cart and automatically fed into the storage unit, from where the system transfers them onto the infeed roller conveyor.

2. Cutting to length – Pieces are precisely aligned on the roller conveyor using pneumatic cylinders, then pushed by the servo pusher into the saw, where they are cut to the programmed length with additional allowance for milling.

3. Optical measurement – The system measures the thickness of each piece and sends the data to the CNC machine to adjust the processing height.

4. Robotic handling – A 6-axis robot precisely positions and moves the pieces onto the processing table.

5. CNC milling – Each sample is finished in a single operation, achieving final dimensions with polished surfaces.

6. Stacking finished pieces – The robot transfers the processed samples onto the outfeed conveyor.

7. Continuous operation – Empty carts are replaced seamlessly while the line remains in operation, ensuring uninterrupted production.

Automated production line with a dedicated CNC router for sample fabrication